Spring 2019

Discipline: Architecture / Interior Design

Year Level: Advanced Interdisciplinary

Professor(s):

Virginia San Fratello, Distinguished Visiting Professor / Associate Professor at San José State University, School of Art & Design / Partner at Rael San Fratello and at Emerging Objects.

Angela Carpenter, Instructor / Fabrication Labs Manager

Description:

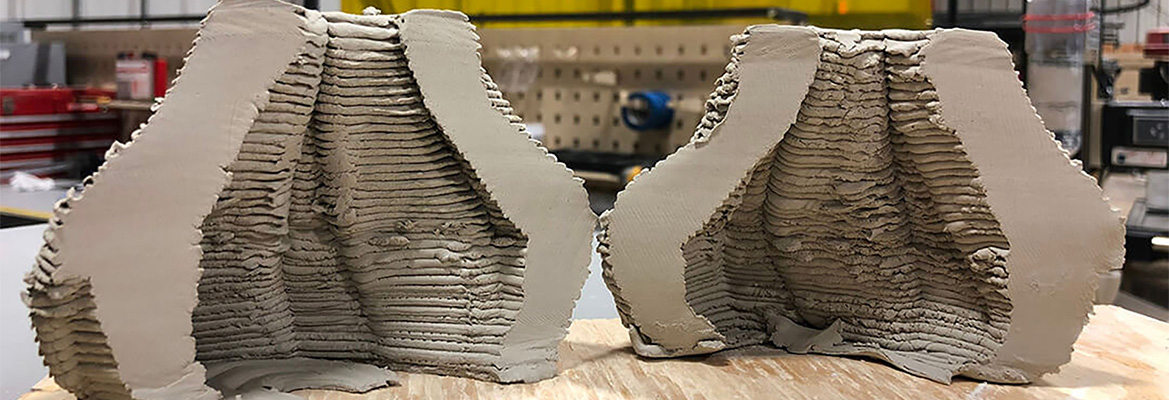

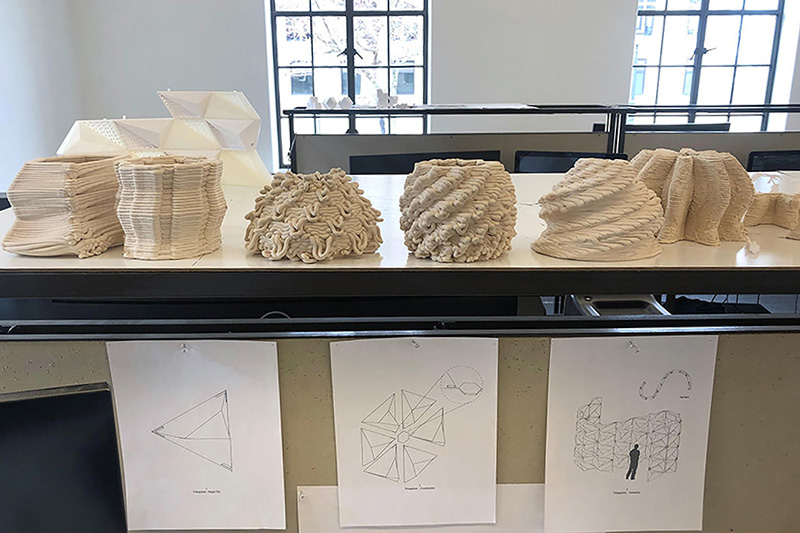

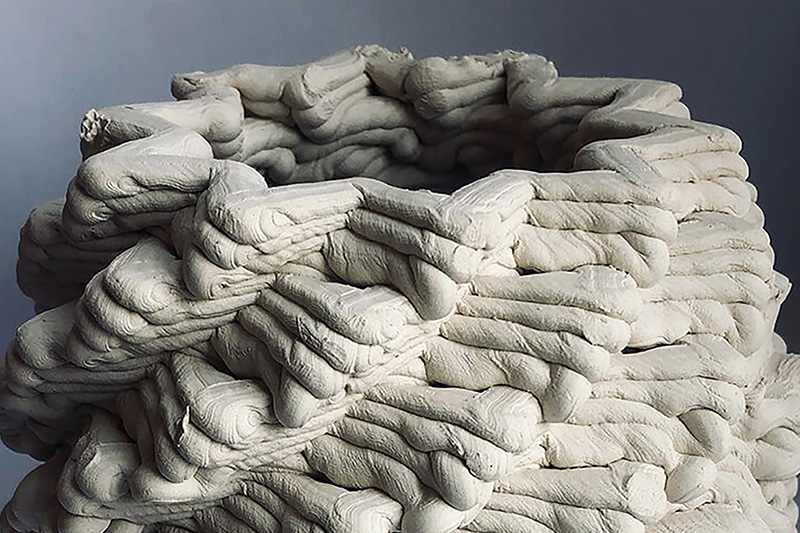

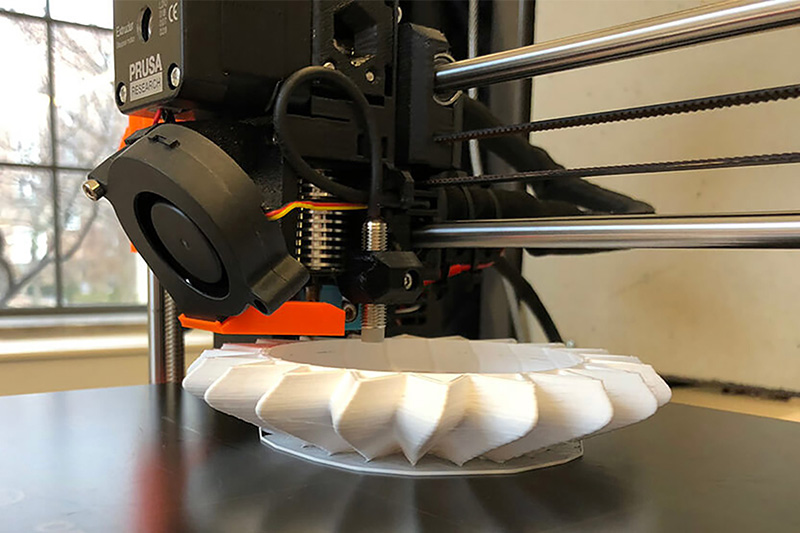

The Printing Architecture studio explored modular, self-connecting componentry through the 3D printing of bio-plastics and clay material. Using small, fundamental building blocks as an example, the studio looked at craft traditions of the past, while considering the potential of the emerging technology of 3D printing. Parallel to the investigation of their components, students tested alternative and new methods for post processing their printed parts. These included dipping them in paint or fingernail polish, coating with fibrous materials, and filling with scented wax.

The initial experimentations were developed into conceptual large-scale systems made from smaller 3D-printed blocks, bricks, or tech-tiles with the consideration of context- and sensory-based conditions as a means of shaping the components. The project goals were for students to engage directly with a manufacturing process and to help shape a new way of fabricating complex structures in the built environment.